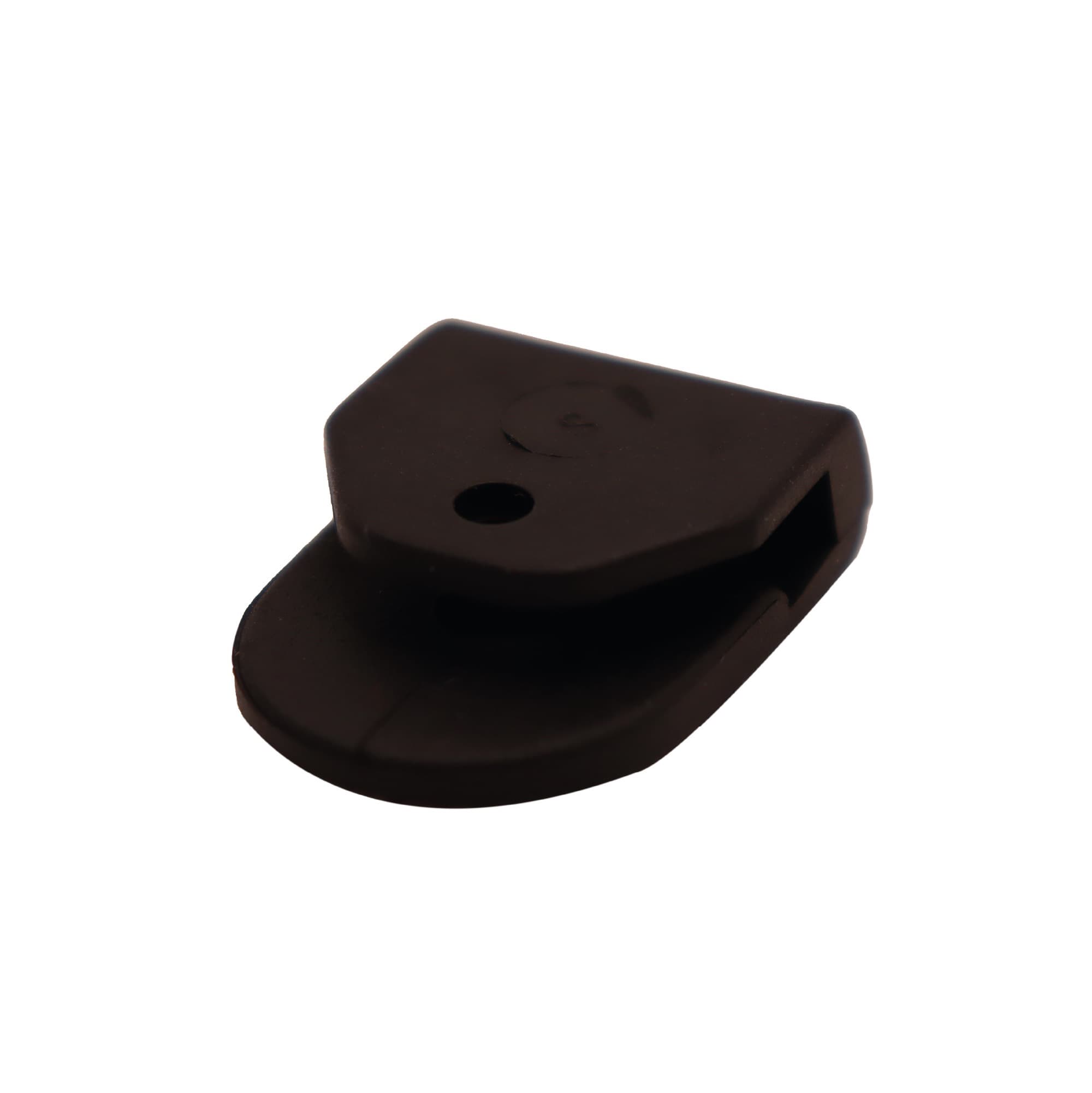

PLASTICS

Plastic injection molding company

A quality solution for large-scale production

Louison Industries, the plastic injection company, offers you a quality solution for your large-scale production needs. With our expertise as a century-old company, we put our proven know-how in the field of plastic injection at your disposal.

Whether you need plastic parts in polyamide, polypropylene, EPDM or other materials, our responsive team can meet your requirements with precision and speed. We understand the importance of respecting your specifications to deliver finished plastic parts that meet your highest quality standards.

Parts tailored to your industrial needs

With a production capacity of up to 400 grams, we are able to produce a wide range of plastic parts adapted to different industrial sectors. Our personalized approach allows you to choose the desired texture for your parts, while benefiting from a wide range of material compositions to meet the specific needs of your applications.

At Louison Industries, we focus on the strength of our plastic parts. Each base material, whether EPDM, polyamide or polypropylene, is carefully selected to ensure optimum strength and durability under a wide range of operating conditions. Our technical expertise enables us to advise you on the material best suited to your needs.

Plastic injection process

As a state-of-the-art plastic injection company, we guarantee the highest standards of quality.

The thermoplastic pellets, 2 to 3 mm in diameter, are carefully sucked into a hopper and then heated to high temperature. The molten, malleable material is then injected into the mold, selected according to your specifications.

Our high-precision injection molding machines apply high pressure to allow the plastic to spread evenly in the mold, giving it its final shape. In just a few seconds, the part cools and solidifies, ready to be ejected into a collection tray.

Integrating an automated system into our plastic injection process enables us to minimize production costs, increase productivity and offer you exceptional value for money. Thanks to our technical approach, we are able to produce high-quality plastic parts at a sustained rate, without compromising on precision and reliability.

Economic and technical benefits

Our plastic injection business offers a multitude of economic and technical advantages that make it an essential solution for your industrial production. Our plastic injection process is designed to maximize productivity while reducing costs, enabling you to achieve your objectives while staying within your budget.

Thanks to our large-scale production capacity, we can meet high-volume demands with competitive lead times. Our team works closely with you to understand your specific needs and provide customized solutions tailored to your industry.

The weight-to-solidity ratio of our plastic parts is a major advantage, enabling you to reduce the overall weight of your finished products while guaranteeing their durability and strength. This opens up innovative design possibilities, while optimizing the efficiency of your applications.

Expertise in plastics processing

Our expertise as a plastic injection company is backed by decades of experience in plastic processing. We understand the nuances of each material and can guide you in making the optimum choice for your plastic parts. Our skilled technicians closely monitor every stage of the injection process, ensuring the consistent quality of every part that leaves our facilities.

We continually invest in research and development to stay at the forefront of the plastics industry. Our commitment to innovation enables us to adopt the latest technologies and best practices, ensuring that your plastic parts are manufactured using the most advanced and efficient methods.

At Louison Industries, we are committed to providing you with plastic parts that exceed your expectations in terms of quality, durability and performance. Our reputation as a trusted plastic injection company rests on our commitment to excellence and our dedication to customer satisfaction.

OUR APPROACH

Consulting, research and manufacturing

Our innovative approach allows us to accompany you as a true partner, from the project idea to the industrialization of the finished product.

Consulting

Our large experience in the world of textiles and plastics processes enables us to advise and guide you in your choice of products. If you encounter technical problems with one of your textile or plastic products, we are here to find solutions. Tell us about your projects so that we can help you solve your problems. We are no longer just your supplier, we become your partner!

R & D

Basic and experimental research is in the company's DNA. We are always on the lookout for new technologies from our suppliers and partners, so that we can offer you the most innovative solutions on the market. Our 2 laboratories allow us to carry out all kinds of research, development and tests quickly in order to develop and perfect new manufacturing processes and new materials.

Manufacturing

We are able to design products from existing models or we can create a new product based on your specifications or a jointly developed specification. We study the constraints linked to the realization of your product, and we propose the most economical solution that meets your needs. If we can integrate a large part of eco-responsibility from the design stage, we will do so with passion.

FAQ | Plastic injection molding company

What is plastic injection molding?

Plastic injection molding is a manufacturing process used to produce plastic parts. It involves injecting molten plastic into a mold, where it cools and hardens to form the fina

How does the plastic injection process work?

The plastic injection process begins with the heating of plastic granules in a cylinder of the injection machine. A metering screw pushes the molten plastic at high pressure into a cavity-shaped mold. After cooling, the molded part is ejected from the mold.

What types of plastic can be used in the plastic injection process?

A wide variety of plastics can be used, such as polypropylene (PP), polyethylene (PE), polystyrene (PS), polyurethane (PU), polycarbonate (PC) and many others. The choice of plastic depends on the characteristics required for the final part.

What are the key elements of an injection molding machine?

A plastic injection molding machine consists mainly of three key components: the injection system (comprising cylinder, screw and nozzle), the mold (which defines the shape of the part) and the clamping system (which holds the mold firmly in place).

What are the stages in the plastic injection process?

The steps in the plastic injection process include closing the mold, injecting the molten plastic, cooling and solidifying the plastic, opening the mold and ejecting the molded part.

What industries use plastic injection molding?

Plastic injection molding is widely used in many industries, such as automotive, electronics, household appliances, toys, packaging, medical, aerospace, among others.

What factors need to be taken into account for a successful plastic injection molding project?

Some important factors include mold design and optimization, choice of appropriate plastic, control of process parameters (temperature, pressure, injection speed, etc.), and quality control throughout the production process.

What are the limits of plastic injection molding?

Some of the limitations of plastic injection molding include the high initial cost of creating the mold, and the time needed to make the mold.

A project ?

Contact us

With LOUISON INDUSTRIES, benefit from more than 140 years of know-how and experience in the field of textiles and plastics processes.